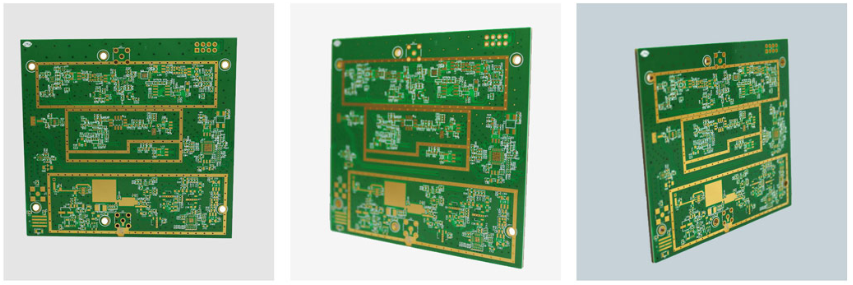

6-layer Rogers + FR4 Mixed Medium High-frequency PCB

Product Description

keywords: 6 Layer High Frequency PCB, Rogers FR4 PCB, High Frequency PCB Boards, High Quality Multilayer PCBs, High Frequency PCB Material

Layers: 6 Layers

Special Process: Mixed media, gold fingers

PCB Material: ROGERS 4350 + FR4

Surface treatment: Immersion Gold

Outer line width / line spacing: 7/7mil

Inner layer line width / line distance: 5/5mil

Board thickness: 2.3mm

Minimum aperture: 0.6mm

6-layer Rogers + FR4 Mixed Medium High Frequency Printed Circuit Board

6-layer Rogers + FR4 mixed medium high frequency PCB? Can such difficult high-frequency PCB also be manufactured? Yes, we can. Jinghongyi PCB is a high-end PCB manufacturer specializing in high-precision Multilayer PCB, high Tg PCB, impedance control PCB, BGA PCB, and high-frequency high-speed RF PCB. Materials used in PCB production, such as Rogers, FR4, etc., are in stock, and we have a very good cooperation relationship with material suppliers, which can ensure the timely supply of raw materials, ensure the controllable production schedule, and meet the requirements of the delivery cycle.

What is High Frequency printed circuit board?

High frequency printed circuit board refers to the special circuit board with high electromagnetic frequency, which is used in the fields of high frequency (frequency greater than 300MHz or wavelength less than 1m) and microwave (frequency greater than 3GHz or wavelength less than 0.1M). The high-frequency PCB is a circuit board produced by a partial process of a conventional rigid PCB board manufacturing method on a microwave substrate copper clad board or by a special processing method.

Generally speaking, high-frequency PCB can be defined as a circuit board with a frequency above 1GHz.

Features of high-frequency PCB:

1. High efficiency

The high-frequency circuit board with a small dielectric constant will also have a small loss, and the advanced induction heating technology can achieve the target heating demand with high efficiency. Of course, while focusing on efficiency, it also has the characteristics of environmental protection, which is very suitable for the development direction of today's society.

2. Fast

The transmission speed is inversely proportional to the square root of the dielectric constant, meaning that the smaller the dielectric constant, the faster the transmission speed. This is the advantage of the high-frequency circuit board. It uses a special material, which not only guarantees the characteristics of low dielectric constant but also maintains stable operation, which is very important for signal transmission.

3. large controllability

It is widely used in high-frequency circuit boards for the heat treatment of precision metal materials in various industries. In the process of its field, not only can the heating of different depth parts be realized, but also the local characteristics can be heated, whether it is surface or deep. Concentrated or decentralized heating can be done easily.

4. strong tolerance

Dielectric constant and medium have certain requirements on the environment, especially the wet weather will seriously affect the use of the board. High-frequency circuit boards made of extremely low-absorbency materials can challenge such environments, while also having the advantage of resisting chemical corrosion, moisture resistance, high temperature, and great peel strength, making high-frequency circuit boards perform powerfully.

High frequency circuit board material

The substrate material used in the high-frequency circuit board needs to have excellent electrical properties, good chemical stability, and the loss on the substrate is very small as the frequency of the power signal increases, so the importance of the high-frequency board is highlighted.

Therefore, when selecting a substrate for a PCB for a high-frequency circuit, it is particularly necessary to examine the various characteristics of the material DK at different frequencies. For the requirements of high-speed transmission of signal emphasis, or characteristic impedance control requirements, focus on DF and its performance under conditions of frequency, temperature and humidity.

Under the condition of frequency change, the general type of substrate material shows a large change of DK and DF values. Especially in the frequency range of l MHz to l GHz, their DK and DF values change more significantly. For example, a general-type epoxy resin-glass fiber-based substrate material (general type FR-4) has a DK value of 4.7 at a frequency of 1 MHz, and a DK value of 4.19 at a frequency of 1 GHz. Above lGHz, its DK value tends to be flat. The changing trend is smaller as the frequency increases (but the change is not large). For example, at 10 GHz, the DK value of FR-4 is generally 4.15, and the substrate material having high-speed and high-frequency characteristics changes in frequency. In the case of DK, the DK value changes little, and the DK keeps changing in the range of 0.02 from the frequency of change from 1 MHz to 1 GHz. Its DK value tends to decrease slightly from low to high frequency.

The dielectric loss factor (DF) of a general type of substrate material is affected by a change in frequency (especially in a high-frequency range), and the change in DF value is larger than that of DK. The law of change tends to increase. Therefore, when evaluating the high-frequency characteristics of substrate material, the focus of its investigation is on the change of its DF value. There are two distinct types of two types of substrate materials with high-speed and high-frequency characteristics. In general, there are two different types of substrate materials: one is that the (DF) value changes little with frequency. There is also a class that, although similar in magnitude to the general substrate material, has a lower (DF) value.

High-frequency circuit boards with induction heating technology have been widely used in the communication industry, network technology field promotion and high-speed information processing systems to meet the requirements of many high-precision parameter instruments. A reliable high-frequency circuit board provides great help in actual production.

How to choose high frequency high speed PCB material

To select the PCB substrate, a balance must be made among meeting the design requirements, mass production and cost. In short, the design requirements include electrical and structural reliability. Generally, when designing a very high-speed PCB board (frequency greater than GHz), PCB material problem will be more important. For example, the FR-4 material, which is commonly used now, has a large dielectric loss DF (dielectric loss) at several GHz, which may not be applicable.

For example, 10Gb / s high-speed digital signal is a square wave, which can be regarded as the superposition of sine wave signals of different frequencies. Therefore, 10Gb / s contains many different frequency signals: 5GHz fundamental signal, 3-order 15GHz, 5-order 25ghz, 7-order 35GHz signal, etc. The integrity of the digital signal and the steepness of the upper and lower edge are the same as the low loss and low distortion transmission of the RF microwave (the high-frequency harmonic part of the digital signal reaches the microwave frequency band). Therefore, in many aspects, the selection of high-speed digital circuit materials is similar to the requirements of RF microwave circuits.

The main factors to be considered in the selection of suitable base materials are as follows:

1. Manufacturability:

2. Various performances (electrical, performance stability, etc.) matching with products:

Low loss, stable Dk/Df parameters, low dispersion, small variation coefficient with frequency and environment, small tolerance of material thickness and glue content (good impedance control), if the trace is long, consider low roughness copper foil. In addition, the high-speed circuit needs to be simulated in the early stage of design, and the simulation result is the reference standard of the design. "Xingsen Technology-Agilent (High Speed/RF) Joint Lab" solves the performance problems of inconsistent simulation results and tests. It has done a lot of simulation and actual test closed-loop verification, and the simulation can be consistent with the actual measurement through unique methods.

3. The availability of materials in a timely manner:

Many high-frequency board material procurement cycles are very long, even 2-3 months; in addition to the conventional high-frequency board material RO4350 in stock, many high-frequency boards material need to be provided by customers. Therefore, high-frequency plates need to communicate with manufacturers in advance, and prepare materials as soon as possible;

4. Cost:

5. Applicability of laws and regulations:

It should be integrated with environmental protection regulations of different countries to meet the requirements of RoHS and halogen-free.

Among the above factors, the high-speed digital circuit operation speed is the main factor to be considered in PCB material selection. The higher the speed of the circuit, the smaller the DF value of the selected PCB material. The low loss circuit board will be suitable for 10Gb / s digital circuit; 25gb / s digital circuit needs to select the board with lower loss; ultra-low loss board will be suitable for the faster high-speed digital circuits, and its speed can be 50GB / s or higher.

From material DF:

The circuit board material with DF between 0.01 and 0.005 is suitable for the digital circuit with the upper limit of 10Gb / S;

DF between 0.005-0.003 is suitable for digital circuits with an upper limit of 25gb / s;

Circuit board materials with DF no more than 0.0015 are suitable for 50GB / s or even higher speed digital circuits.

Common high-speed PCB materials are:

1) Rogers: ro4003, ro3003, ro4350, ro5880, etc

2) TUC: tuc862, 872slk, 883, 933, etc

3) Panasonic:Megtron4、Megtron6, etc

4) Isola: fr408hr, is620, is680, etc

5) Nelco:N4000-13、N4000-13EPSI, etc

6) ShengYi

Of course, there are many other high-frequency board materials, such as Arlon (acquired by Rogers) and Taconic, which are all old brand RF microwave material factories with guaranteed performance.

Product Categories : High Frequency PCB